Encouraged by my first attempt a grabbed another Redgum blank and the next day I got started on another bowl. Here I was aiming for a different look, straight lines and a feeling of depth from what was essentially a blank the same size as the previous one.

The bowl started out well, but a rookie mistake was made, the mortise I carved for my chuck to expand into was also the base of the bowl, and I wanted it to stand proud of the table a little. So I had a fairly thin (about 5mm) wall. I turned the bowl around to start work on the inside and popped it in my chuck, I was aware of the fragility of the wood (this redgum is also very dry and hard, almost brittle) so I was careful tightening the chuck, but to no avail. Almost immediately I took a tool to the wood the joint cracked, and the bowl went flying off across the workshop. Lesson learnt.

Luckily I still has wood I could work with, so I screwed my faceplate back on, cut the mortise into the base again, giving it the strength of the bulk of the wood and then flipped it and popped it back on the chuck. From here it went smoothly, and I was very happy with the result.

- Preparing a blank to turn

- Happy with the shape I put it into the chuck

- Starting to turn, a dab of superglue

- The mistake, snapped clean off!

- The mistake, snapped clean off!

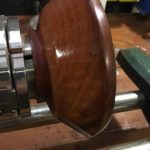

- Recutting the base

- Looks betetr now, ready to chuck up properly

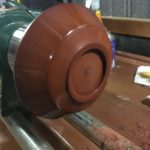

- Hollowing the bowl

- Polished, and done!

- Fresh bowl, straight from the lathe

- Finding a fancy way to photograph my work

- What’s this? Says Bowie the curious cat

- Am I in the photo?

- The finished piece